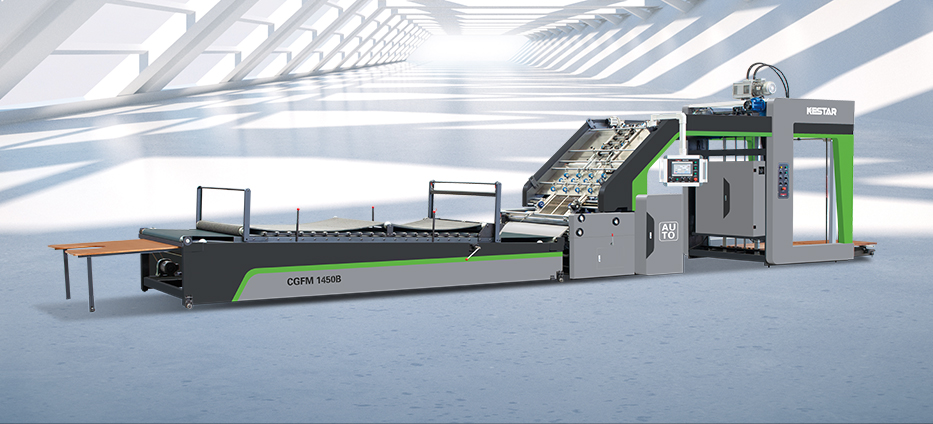

The machine adopts the perfect combination of motion control system and servo correction system, using multiple sets of high-precision photoelectric sensors to track and position the paper, and correct the paper through the servo motor to achieve precise bonding of the top paper and the bottom paper. A high-speed drawing positioning structure is adopted to further optimize the requirements for the accuracy of the side surface of the top paper and the bottom paper. The machine adopts a humanized control system and realizes one-key adjustment function. It has the advantages of fast speed, high precision and convenient operation.

CGFM-1450B Specifications| Model | CGFM-1450B |

| Max. Paper Size | 1450X1300mm |

| Min.paper Size | 400X400mm |

| Paper Thickness | 150-600g |

| Base Paper Thickness | ABCDEF ≤ 10mm |

| Max.Speed | 130m/min |

| Lamindin Precision | ±1mm |

| Total Power | 21KW |

| Weight | 6000Kg |

| Overall Dimension | 12.5×2.5× 2.3M |

| subject to change without notice. | |

| Model | GZFM-1650B |

| Max. Paper Size | 1650×1300mm |

| Min.paper Size | 400×400mm |

| Paper Thickness | 150-600g |

| Base Paper Thickness | ABCDEF ≤ 10mm |

| Max.Speed | 130m/min |

| Lamindin Precision | ±1mm |

| Total Power | 21KW |

| Weight | 7000Kg |

| Overall Dimension | 12.5×2.5×2.5M |

| subject to change without notice. | |

●High speed: the highest speed is 10000 sheets/hour

●Convenient: One-key adjustment of the whole machine, servo compensation positioning, and the amount of paper advance can be adjusted at will