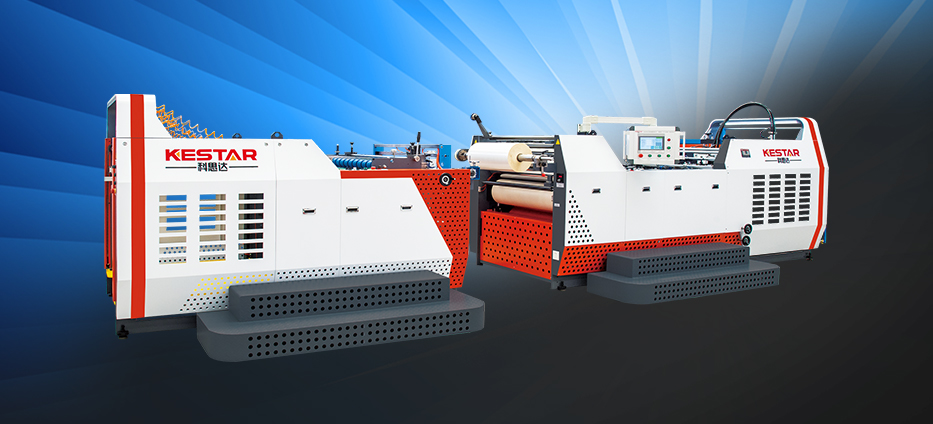

YFM Series film laminator is a dual purpose machine designed for thermal film and non-glue film. This machine uses Feida automatic paper feeding mechanism to send paper to the matching host.Then the film is laminated with the sheet by pressing roller through heating and pressing. The pressing roller adopts circulating water heating system with quick heating and stable and accurate temperature control. The finished product can be delivered with roll or be cut a notch by the rotary disk knife and separated by rollers. The delivery can be either manually or automatically. Mainly used in books and periodicals cover, calendar, self-adhesive, carton and other packaging fields.

YFM-1050X950

| Model | YFM-1050X950 |

| Max. paper size | 1050X950mm |

| Min.paper size | 380X260mm |

| Laminating speed | 10-105m/min |

| Appropriate paper | 105-500g/m2 |

| Total Power | 30kw |

| Weight | ≈5.5T |

| Overall dimension | 8500x2650x1950mm |

| Note: subject to change without notice. | |

| Model | YFM-1100X1200 |

| Max. paper size | 1100X1200mm |

| Min.paper size | 400X310mm |

| Laminating speed | 10-105m/min |

| Appropriate paper | 105-500g/m2 |

| Total Power | 34kw |

| Weight | ≈6.2T |

| Overall dimension | 10350x2650x1950mm |

| Note: subject to change without notice. | |

| Model | YFM-1100X1450 |

| Max. paper size | 1100X1450mm |

| Min.paper size | 400X310mm |

| Laminating speed | 10-105m/min |

| Appropriate paper | 105-500g/m2 |

| Total Power | 36kw |

| Weight | ≈7.2T |

| Overall dimension | 10350x2650x1950mm |

| Note: subject to change without notice. | |

| Model | YFM-1300X1650 |

| Max. paper size | 1300X1650mm |

| Min.paper size | 450X450mm |

| Laminating speed | 10-110m/min |

| Appropriate paper | 157-500g/m2 |

| Total Power | 38kw |

| Weight | ≈7.5T |

| Overall dimension | 11750x2850x1950mm |

| Note: subject to change without notice. | |

●The feeder is equipped with pre-loading devices, which allows feeding paper without stopping the machine.

●Vacuum adsorption paper convey, two wide belt conveyor no need adjustment.

● The press wheel + wool wheel moves as a whole with quickly and accurately adjustment.

●The powder removal device adopts hot-pressing static mechanism, sticking powder and pre-heating the paper, thus enables the machine to run at a high speed.

●The main machine laminating roller adopts a new electromagnetic heating system, which can timely compensate the heat taken away by the paper at high speed, and ensure the isothermal error of the roller less than 2℃ .

●The laminating roller adopts gas-liquid supercharger combined with 80 diameter hydraulic cylinder, 8MPa can ensure normal production, and the system is durable without oil leakage.

●Equipped with pneumatic shaft and film lifting device, it is easy for film loading.

●Automatic film- tension- control system ensures smooth film feeding.

●Optional paper up gas shaft for customers to choose roll delivery or directly separating.

● Optional rewinding and unwinding shaft, can be cut after winding and shaping.

● Rotary knife + emery cloth knife, ensure cutting stability and reliability at high speed.

●The delivery unit uses vacuum suction feeding, which makes more smooth paper transferring.

●Automatic pivoting device allows sheet to be transferred into the manual delivery unit when delivery in trouble.

●The paper bending device used for delivery, enhances the paper deflection.

●Intermittent air flow used under the paper facilitates thinner or warped paper to be delivered quickly.

●4 sets of side jogger and one set back jogger ensures tidy delivery of big size strip paper.

●Feida paper feeding system

●Heating system

●Receiving Department