The machine is perfectly combined with the motion control system and the servo correction system. It uses multiple sets of high-precision photoelectric sensors to track and position the paper, and corrects the paper through the servo motor to achieve accurate positioning of the paper and the bottom paper. It has many advantages such as high speed, high precision, convenient operation, etc. It is an indispensable equipment for color printing and packaging users.

CGFM-1450A| Model | CGFM-1450A | |||

| Max. Paper Size | 1450X1300mm | |||

| Min.paper Size | 400X400mm | |||

| Paper Thickness | 150-600g | |||

| Base Paper Thickness | A、B、C、D、E、F ≤ 10mm | |||

| Max.Speed | 150m/min | |||

| Lamindin Precision | ±1mm | |||

| Total Power | 20KW | |||

| Weight | 7500Kg | |||

| Overall Dimension | 13.5X2.3X 2.5M | |||

| subject to change without notice. | ||||

| Model | CGFM-1650A | |||

| Max. Paper Size | 1650X1450mm | |||

| Min.paper Size | 400X400mm | |||

| Paper Thickness | 150-600g | |||

| Base Paper Thickness | A、B、C、D、E、F ≤ 10mm | |||

| Max.Speed | 150m/min | |||

| Lamindin Precision | ±1mm | |||

| Total Power | 22KW | |||

| Weight | 8000Kg | |||

| Overall Dimension | 14X2.5X2.5M | |||

| subject to change without notice. | ||||

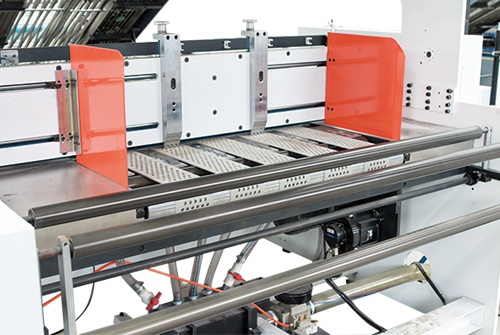

●Suction belt feeding department

●Front edge paper feeding section

●Servo positioning unit